Secondary Operations

Diverse Single Source Tube Bending Fabrication Capabilities

Triad Products Corp. is the single-source supplier you need for your tube bending and fabrication projects. Choosing one vendor for all your tubing fabrication processes means better project control, smooth communication, cost-effective solutions, and increased overall value. We are ready, willing, and able to serve as your single-source vendor for a wide range of short- and medium-run projects with quantities in the hundreds or thousands.

Our tube bending fabrication capabilities are offered as stand-alone operations and as elements of your larger manufacturing project. We specialize in bending tubing from 1/8" to 1". We work with a variety of tubing materials, including stainless steel, steel, aluminum, copper, and brass, as well as wire, sheet metal, and plastic. This greatly increases the range of projects we can see to completion. No matter your material or size, we can do it all.

To learn more about our secondary operations for custom tube fabrication, contact Triad today, and we will happily discuss your project and tubing needs.

Secondary Operations for Custom Tube Fabrication

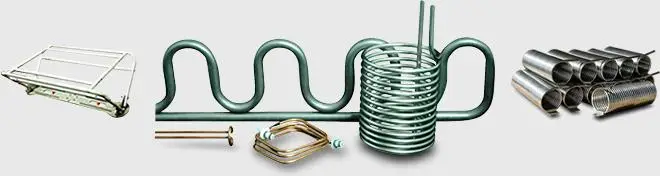

We work with a wide range of tube bending, fabrication, and assembly projects. Projects include custom bending fabrication for gas and fluid supply lines, tubular handles, manifolds, and chipping gun nozzles. Triad’s custom tube bending secondary operations used for these projects include:

- Tube Threading: Standard pre-bend tube threading and custom post-bend tube threading, with options for customized threaded length, pitch, depth, and internal and external threading.

- Tubing End Configurations: Custom tube fabrication options include flaring, swaging, reducing, punching, piercing, drilling, threading, flattening, and final assembly.

- Tubing Fabrication: Full customizations including cutting, drilling, piercing, notching, CNC machining, and MIG, TIG, and resistance welding.

- Tubular Assemblies: Capabilities to deliver complete, ready-to-use bent tubular assemblies and products.

- Brazing & Silver Soldering: Complete brazing and low-temperature silver soldering services using a silver alloy with a higher melting point than standard soldering material.

Contact Triad for Full Service Tube Bending, Fabrication, & Finishing

At Triad Products Corp., our greatest strengths are our versatility and experience. We have what it takes to deliver complete, ready-to-use tubular parts and components for your application, specializing in quantities from 100 to 1000. Our secondary operations ensure we are your one-stop solution for all your tubing needs.

Request a quote on your project or contact us to learn more about our diverse range of secondary operations.

Machinist bending 3/8” steel tubing.

Machinist examines bent & flattened steel tubing.

Final assembly of the folding steel tube handle.

Machinist drills hole during the final assembly process.

Tubing assembly ready for shipping.