Custom Stainless Steel Tube Bending

Custom Stainless Steel Tube Fabrication Services

Stainless steel provides the same strength as steel but offers better corrosion resistance and has a bright, low-maintenance surface finish preferred for applications where the tubing is exposed. Custom stainless-steel tubing is manufactured using different types of machinery and methods depending on the bend angle, wall thickness, outside diameter, and centerline radius.

For over 30 years, Triad Products has been a leader in stainless steel tube bending & fabrication. We focus on small to medium production runs ranging from 100 to 1000 pieces to accommodate projects and design variations that can’t be handled by other tube bending operations. Join the hundreds of OEMs coast to coast who consistently rely on Triad Products as their single source supplier for stainless steel tubing. View custom options below. Request a quote today to get started.

Stainless Steel Tubing Applications & Industries

We offer custom stainless steel tubing components for a wide range of OEM industries and applications. Visit our Bent Stainless Steel Tubing Photo Gallery to see more examples of our stainless steel tubing and fabrication projects.

Stainless Steel Tube Bending for OEM Equipment

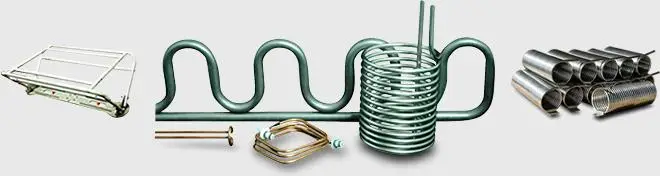

Stainless steel tube bending is used to manufacture bumpers and tubular handles for different types of OEM instruments and machinery. Bumpers and handles can be formed for stationary and portable equipment on varying sizes, and in the exact length you need. We can also weld and apply finishes to your custom stainless steel tubing upon request.

Stainless Steel Tubing for Manifolds and Hydraulic Fluid Supply Lines

Tubing is used to transport hydraulic fluid to and between power transfer components. Custom stainless-steel tubing is an excellent choice for hydraulic fluid applications because it is low maintenance and can handle higher operating temperatures than hoses. We can also custom bend stainless steel tubing for manifold assemblies that regulate flow between pumps and other hydraulic components.

.jpg)

Stainless Steel Tubing for Cooling Coils

Stainless steel is ideal for cooling coils because it is corrosion resistant, and heat and chemical resistant. We bend stainless steel tubing in the radius and pitch required for your cooling application and can add end configurations to deliver a finished product. Our specialists will work with you to determine the tubing size needed to achieve the desired pitch and radius. We can also assist with design variations as needed.

Stainless Steel Tubing for Water Nozzles

Because of the non-corrosive quality of stainless steel, custom bent stainless steel tubing is used in a full range of fluid supply line applications. This photo is an example of custom stainless-steel water nozzles, made from ½” stainless steel tubing, 4.5” long. This water nozzle includes a 5* bend, with diagonal cuts 2-ways, 51* and 55* degrees. Medium run of 1,000+ parts.

Standard Stainless Steel Tubing Sizes

Triad Products can bend and fabricate steel tubing to meet a wide range of sizes. Standard sizes for steel tubing range from 1/8” to 1” in diameter.

|

|

|

Stainless Steel Tubing Grades

We provide stainless steel tube bending using 304 and 316, and other grades as specified by the customer. Contact us to discuss your material requirements.

The grade you choose determines the type of bending process used along with the radius that can be achieved without damaging the tube. Some stainless steels are harder to bend than other, and applications require a coil or other tight radius will require a different grade than a piece of tubing.

Partner with Triad as your Stainless Tube Bending Manufacturer

Choosing a component manufacturer is an important decision. By researching their production capabilities, quality standards, expertise, and customer service, you will know all you need to select the right OEM supplier for your business. Learn more about what it means to partner with Triad—a trusted OEM manufacturer in tube bending.

Contact Us for Start-to-Finish Custom Tubing & Fabrication

Request a quote to learn more about our custom stainless steel tube bending and fabrication services.

.jpg)

.jpg)

.jpg)