Custom Tube Fabrication

Your Single-Source Provider for Tube Bending & Fabrication

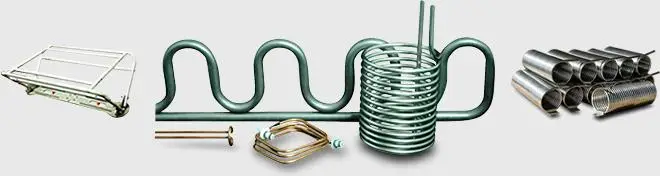

At Triad, tube bending is often just the start of a project where additional fabrication is needed. We’re proud to offer a full range of tube fabrication services, including welding, CNC machining, drilling, piercing, cutting, notching, and finishing. Our custom tube fabrication services mean everything we make is customized directly to your needs. We offer numerous secondary services to serve as your single-source supplier for all tubing processes.

To get started on your custom tubing projects, contact Triad today. Our team will assist you in designing and manufacturing the best solutions for your applications.

Tube Fabrication Capabilities

Triad performs fabrication services to help design your tube to suit your needs. From simple requests to complex geometries, we can create complete, ready-to-use tubing designs for virtually all industrial applications. Our custom tube bending services and fabrication abilities are designed to fulfill all specialty tubing requirements.

Welding

Our precision welding capabilities include MIG, TIG, conventional, and resistance welding. MIG welding is a simple form of welding that uses a constant feed to join metals quickly. TIG welding requires a non-consumable tungsten electrode to manually weld a wide variety of metals and is used for its operational versatility. Triad can also perform conventional and resistance welding operations that do not require a filler material to join materials securely. Our welding services create strong, permanent joints for a variety of tubing fabrication requirements.

Machining

Triad offers CNC and conventional machining to support other manufacturing operations. Our machining processes assist us with custom tube fabrication, allowing for extreme precision and tube bending accuracy. We can create custom tubing bent to virtually any specification. Our team works with you to design the best solutions for your needs.Drilling

While most drilled holes in tubing can only be created near the ends, Triad can drill holes in any location along the length of a tube. We can make holes of any size according to your specifications, and tapping services are available if necessary.

Punching & Piercing

Punching and piercing are highly efficient ways to create holes in the walls of a tube. Punching is a stamping process that uses a mandrel and dies to secure the tube for hole punching. Punched holes are extremely precise with minimal distortion. Piercing does not use dies for support, creating dimpled holes. Triad can use punching and piercing methods to create custom holes that suit your exact tube needs.

Triad’s Custom Tube Fabrication & Secondary Operations

We provide a range of secondary services to ensure all your needs are met in one spot. In addition to tube bending processes, we engage in tube threading, forming tube end configurations, creating tubular assemblies, and brazing or silver soldering tubing materials. Triad Products Corp. is your reliable single-source supplier for all your tube bending and fabrication projects.

Contact Us for Start-to-Finish Tube Bending & Fabrication

Working with just one vendor for all the tubing fabrication processes you need means better overall value with fewer headaches. We are ready, willing, and able to serve as your trusted source for a wide range of short- and medium-run projects, with quantities ranging from 100s to 1,000s.

For a tube bending provider you can trust, Triad is your reliable partner. Request a quote on your project or contact us today to get started on your project.