Brazing & Hard Silver Soldering

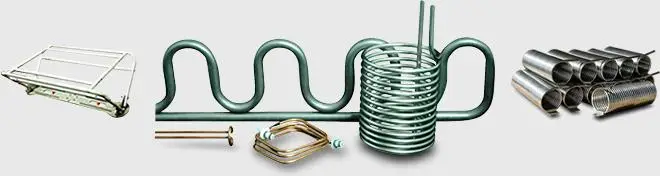

Bent, Flared and Silver Brazed. 5/8" Steel Tube bent into a U shape, with a 1/4" Steel Flared Tubing Silver Brazed in Place. A 1/8" round bar, was silver brazed in place for positioning.

Steel Tube Drain Line. 1" OD steel tube with 3/8 steel flanges, which are silver soldered for assembly. Drain line components are used in large OEM industrial engines.

Custom Brazed or Soldered Tubular Parts & Assemblies

Used to join similar or dissimilar metals, brazing and silver soldering are challenging processes that are part science, part art. They require skill and experience, as melting temperatures need to be closely monitored and materials have to be carefully handled to ensure the quality of the resulting joint. If brazing or soldering is done at too hot or too cold a temperature, the process can fail. What’s more, these processes cannot be performed by robotics or CNC technology—skilled, human operators are required to get the job done correctly.

With more than 40 years of experience in the areas of brazing and soldering, you can count on Triad to deliver the reliable results only few experts in the industry can. Our highly proficient welders can provide you with custom brazed or soldered parts skillfully engineered according to your exact specifications. Request a quote today to begin discussing your project requirements. Contact us for more information.

Brazing vs. Soldering

In brazing, a filler material is heated and melted into seams or gaps between two (or more) metal pieces to permanently bond and join them. This process utilizes higher temperatures compared to soldering and requires a silver alloy with a higher melting point than any of the metals being joined.

While very similar to brazing, soldering uses filler materials that melt at lower temperatures (840°F/450°C or lower). This filler, called solder, is melted into seams or gaps between the metal pieces, and, as it cools and solidifies, bonds to the workpiece and creates a sturdy, permanent joint.

Brazing and soldering both produce sealed, leakproof joints, with minimal physical effects on the treated workpieces. Brazing and soldering can be used to create anything from gas and fluid transfer components to PCBs and other electrical conduits.

The Right Process for Your Application

Triad’s expertise in soldering and brazing includes knowing which process is right for the project at hand. Depending on the materials involved and the performance and application requirements, we will determine which option is best for your products.

Brazing of Ferrous Metals

|

Advantages:

|

Disadvantages:

|

Low-Temperature Silver Soldering

|

Advantages:

|

Disadvantages:

|

Learn Why Leading OEMs Choose Triad

Choosing a component manufacturer is an important decision. By researching their production capabilities, quality standards, expertise, and customer service, you will know all you need to select the right OEM supplier for your business.

Learn more about what it means to partner with Triad—a trusted OEM manufacturer in tube bending.

Contact Us for Custom Brazed or Soldered Tubular Parts & Assemblies

Brazing and soldering are just two of the many fabrication processes that Triad Products offers. We provide complete, turnkey manufacturing for custom tubular parts and tubular assemblies, as well as a wide range of secondary operations. Request a quote or contact us today to get started on your project. Triad Products specializes in small to medium production runs, ranging in the 100's to 1000's.

Bent, Flared and Silver Brazed. 5/8" Steel Tube bent into a U shape, with a 1/4" Steel Flared Tubing Silver Brazed in Place. A 1/8" round bar, was silver brazed in place for positioning.

Steel Tube Drain Line. 1" OD steel tube with 3/8 steel flanges, which are silver soldered for assembly. Drain line components are used in large OEM industrial engines.