Tube Threading Services

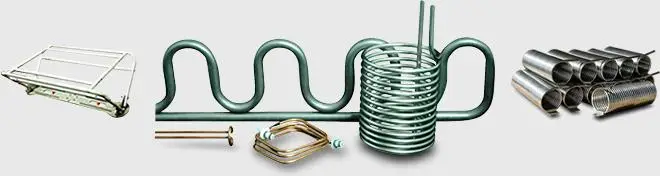

Examples of different length and diameter copper tubing threaded pre and post bending.

Pre And Post Tube Bending Threading Customized to Meet Your Needs

Tube threading involves creating screw-threaded ends to form tubing assemblies and create secure connections between fittings. Triad Products offers custom-made tube threading solutions to meet your specific application requirements. Our skilled tubing specialists utilize specialized machinery that allows us to create custom pre-and post-bend threading in quantities ranging from hundreds to thousands of pieces. Triad’s tube threading process is a secondary value-added operation done in conjunction with a larger project. We offer the unique advantage of threading tubes after the bending process. This specialized capability offers higher-quality tubing components that secure connections while reducing leaks and exposed threading.

Request a quote on our tube threading services today or contact us to learn more about our pre-bent tubing threading and finishing services.

The Importance of Choosing Custom Tube Threading Services

Tube threading involves creating screw-threaded ends for assembly and is used for a variety of OEM applications. Threaded tubing that is mass-produced or purchased through large retailers often comes in standard thread lengths that are too long or short for your application. The result is less secure fittings and unsightly exposed threading on appliances and decorative lighting fixtures.

Additionally, tube benders located overseas may offer threaded tubes, but their threaded products are almost exclusively produced in bulk. This means that customers must select a tubing option that is “good enough” for their needs.

Triad Offer a Superior Custom Tube Threading Solution

Working with a company that offers tube bending and threading services is the best and most efficient way to get a finished product that looks good and meets your exact design requirements. Triad offers internal and external custom tube threading in any size or length and can work with tubing or solid stock tubing. Our capabilities include:

- Threading upon all standard tubing sizes

- Tube threading up 1/2” diameter or larger upon special request.

- End configurations such as flattening, punching, and 37- and 45-degree flaring.

Tube Threading For Lighting Fixtures, Electrical Conduits & More

Pre-Bend and Post-Bend Tube Threading Services

Electrical applications typically involve adding a straight tube threading, while plumbing applications usually require a tapered tube threading. Straight tube threading is not self-sealing and is commonly for electrical tubing applications. When used for plumbing, straight threaded tubes must be used with a plastic or rubber seal to prevent leakage. Triad specializes in straight tube threading for multiple industries. Specific use cases include but are not limited to:

- Decorative light fixtures

- Electrical conduits

- Plumbing fixtures

- Commercial shower fixtures

- Fire sprinkles & More

Contact us to learn more about our customized tube threading services and discuss your project design.

Customized Tube Threading that Meets Your Specifications

Our specialized machinery allows us to do custom pre-and post-bend threading in quantities ranging from hundreds to thousands of pieces. We can quickly and efficiently add customized threads to bent tubing to match your requirements. Our in-house machining capabilities allow us to inspect tubing for quality at each step of the manufacturing process. We can add threads to tube ends, center sections, and any other part of the tubing that needs it. We take a number of factors into consideration prior to creating a tubing prototype, such as:

- Threaded section length

- Thread pitch

- Thread depth

- Materials used

Threading Tubes Pre-Bending vs. Post-Bending

Threaded tube bending involves first threading the tube and then placing it into a piece of equipment for bending. If not done carefully, the threading can be damaged during the bending process. This can especially be an issue in high-volume, fully automated processes. Threading pre-bent tubing eliminates these issues by first bending the tubing and then adding customized threading to the ends.

By researching their production capabilities, quality standards, expertise, and customer service, you will know all you need to select the right OEM supplier for your business. Our skilled machinists will work with you to determine which tube threading process is best for your application. Still have questions? Connect with an expert!

Tube Threading Materials Used

Threading can be added, post-bending, to tubing in any size and material with which we work—if we bend it, we can thread it. Popular materials include:

- Aluminum

- Stainless Steel

- Copper

- Steel & more

Tube Threading & Additional Value-Added Services

Triad is one of the few tube bending companies in the U.S. that offers tube threading post-bending. We also offer several other secondary and finishing services, including Tubing End Configurations, Bent Tubular Assemblies and Brazing & Hard Silver Soldering. Additional customization options that can be performed post-bending include flaring, drilling, welding and much more. View photos of our fabrication and secondary services below:

Contact Us for Custom Tube Threading and Bending

To learn more about our custom threading of tubes post bending, Contact us or Request a quote today. We specialize in small to medium production runs, ranging in the 100's to 1000's.